Barcode technology has evolved from a simple inventory tracking tool into an indispensable asset for small businesses seeking operational efficiency, cost savings, and competitive advantage. In 2025, implementing the right barcode system can transform your business operations, reducing errors by up to 90% while delivering return on investment within just 6-12 months. This comprehensive guide explores everything small business owners need to know about barcode technology, from fundamental concepts to advanced implementation strategies.[1][2]

Understanding Barcode Technology: The Foundation

Barcode technology represents a sophisticated method of automatic identification and data capture that converts product information into a visual pattern readable by optical scanners. At its core, a barcode serves as a visual representation of data encoded in parallel lines, spaces, or geometric patterns that machines can rapidly decode and translate into actionable information.[3][4]

The technology operates through a straightforward yet powerful process: when a scanner’s light source illuminates a barcode, the dark bars absorb light while the lighter spaces reflect it back to the scanner’s sensor. This optical data is then converted into electrical signals, decoded into alphanumeric characters, and transmitted to connected software systems where the information is interpreted and utilized for inventory management, sales transactions, or asset tracking.[5][3]

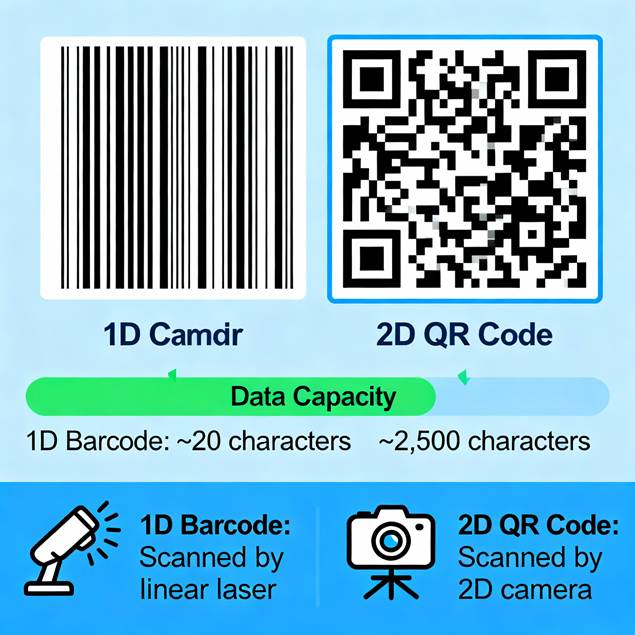

Visual comparison between 1D linear barcodes and 2D matrix barcodes

Types of Barcodes: 1D vs 2D Technology

One-dimensional barcodes systematically represent data by varying the widths and spacings of parallel lines arranged horizontally. These linear codes remain the most recognized barcode format, commonly seen on retail products worldwide. Popular 1D symbologies include UPC (Universal Product Code) used primarily in North America, EAN (European Article Number) for international markets, Code 39 for industrial applications, and Code 128 for alphanumeric encoding.[3][4]

The simplicity of 1D barcodes translates to several advantages: they are inexpensive to produce at approximately $0.01-$0.05 per label, can be scanned rapidly with basic laser scanners, and maintain universal compatibility across scanning infrastructure. However, their linear structure limits data capacity to roughly 20-30 characters, provides no built-in error correction, and makes them susceptible to damage from scratching or fading.[6][4][7][3]

Two-dimensional barcodes encode data across both horizontal and vertical axes, creating matrix patterns of squares, dots, or hexagons that store substantially more information in a compact space. The most prevalent 2D symbologies include QR codes capable of holding up to 7,089 numeric characters, Data Matrix codes preferred in aerospace and pharmaceuticals, PDF417 codes used on driver’s licenses, and Aztec codes employed for transportation tickets.[3][8][4][9]

The enhanced capabilities of 2D barcodes provide compelling benefits: massive data capacity allowing encoding of complete product information, URLs, or serial numbers; built-in error correction enabling successful scans even when up to 30% of the code is damaged; and the ability to be scanned from any direction without requiring precise alignment. Modern smartphones can readily scan 2D barcodes using their built-in cameras, eliminating the need for specialized scanning hardware.[8][6][3]

| Feature | 1D Barcodes | 2D Barcodes |

| Data Encoding | Horizontal axis only | Horizontal and vertical axes |

| Data Capacity | Up to 30 characters | Up to 7,089 characters |

| Error Protection | No built-in correction | Yes, up to 30% damage tolerance |

| Hardware Requirements | Laser scanner or smartphone | Smartphone or imaging scanner |

| Cost per Label | $0.01 – $0.05 | $0.05 – $0.15 |

| Durability | Susceptible to damage | Highly damage-resistant |

| Best Applications | Retail checkout, basic inventory | Healthcare, logistics, complex tracking |

UPC/EAN barcodes remain dominant in 2025, but QR codes are rapidly gaining market share, representing 25% of all barcode usage.

Barcode Scanner Technology: Choosing the Right Equipment

Scanner Types and Technologies

Laser Scanners utilize a focused laser beam to read 1D barcodes with exceptional speed and accuracy, particularly effective for scanning from distances up to 24 inches. These scanners excel in retail checkout environments and warehouse operations where rapid scanning of linear barcodes is essential. Entry-level laser scanners range from $150-$300, while professional models cost $500-$800.[10][11][12]

CCD (Charge Coupled Device) Scanners employ multiple small sensors arranged in a row to capture barcode images at close range, typically 1-3 inches from the code. Their durability and affordability make them ideal for retail stockrooms and inventory management tasks, with prices ranging from $100-$400. However, not all CCD scanners support 2D barcode reading.[11][10]

Image-Based Scanners utilize camera technology to capture and decode both 1D and 2D barcodes through advanced image processing software. Their sophisticated error correction capabilities enable successful scanning even of damaged or poorly printed codes, making them invaluable for logistics and healthcare applications where label condition may deteriorate. Professional image scanners typically cost $300-$1,200.[10][11]

Mobile Barcode Scanner Apps transform smartphones and tablets into versatile scanning devices through specialized software applications. These solutions offer exceptional portability and flexibility for small businesses, field services, and temporary operations, with most apps available for free or under $50. Popular applications include QR & Barcode Scanner by Gamma Play with over 500 million downloads, Google Lens offering integrated search capabilities, and industry-specific solutions like Scandit for enterprise operations.[13][10]

| Scanner Type | Barcode Support | Scan Distance | Price Range | Durability | Best For |

| Laser Scanner | 1D only | Long (up to 24″) | $150-$600 | High | Retail checkout, warehouses |

| CCD Scanner | 1D, some 2D | Short (1-3″) | $100-$400 | Very High | Stockrooms, inventory |

| Image Scanner | 1D and 2D | Medium (4-10″) | $300-$1,200 | High | Logistics, healthcare |

| Mobile App | 1D and 2D | Short (2-6″) | Free-$50 | Low | Small businesses, fieldwork |

Modern barcode scanners offer three primary connectivity options, each suited to different operational requirements. Wired USB scanners provide reliable, uninterrupted operation without battery concerns, making them ideal for fixed workstations like retail checkout counters. Wireless Bluetooth scanners deliver mobility and flexibility for warehouse environments where workers move throughout facilities, typically offering operating ranges of 100-300 feet. Wi-Fi networked scanners enable real-time data synchronization across large facilities with multiple users accessing centralized systems simultaneously.[14]

Implementation Costs: Budgeting for Success

Small businesses can implement effective barcode systems with surprisingly modest initial investments. A basic yet functional setup typically requires $1,500-$3,000 upfront, encompassing one mid-range barcode scanner ($300-$600), a thermal label printer ($300-$500), initial label supplies ($100-$200), and software subscriptions starting at $50-$150 monthly.[12][15]

Mid-range implementations serving growing businesses with 10-50 employees typically invest $3,000-$8,000, including multiple professional-grade scanners ($500-$1,200 each), industrial thermal printers ($800-$2,500), comprehensive inventory management software ($150-$400 monthly), and expanded label materials. Enterprise-level solutions for larger operations exceed $10,000, featuring rugged mobile computers with integrated scanning ($1,200-$3,000 each), high-volume industrial printers ($2,500-$5,000), advanced warehouse management systems ($400-$1,000+ monthly), and specialized labeling solutions.[12]

Initial setup costs vary significantly by business size, with entry-level systems starting around $1,500 and enterprise solutions reaching $8,000+.

For businesses selling products through retail channels or online marketplaces like Amazon and Walmart, obtaining legitimate GS1 barcodes is essential. GS1 offers two primary options: individual GTINs (Global Trade Item Numbers) licensed at $30 each with no annual renewal fee, ideal for businesses with fewer than 10 products; or GS1 Company Prefixes starting at $250 initially plus $50 annual renewals, which enable businesses to generate their own UPC/EAN codes for multiple products.[1][16][17]

The pricing structure scales based on the number of codes required: 10 codes cost $50 annually, 100 codes $100-$140 annually, 1,000 codes $360-$500 annually, and 10,000 codes $500-$830 annually. For internal inventory tracking only—not retail sales—businesses can generate free barcodes using standard symbologies like Code 39 or Code 128 without GS1 licensing.[18][16][19][1]

Beyond obvious hardware and software expenses, several hidden costs frequently catch businesses unprepared. Data preparation and cleanup typically requires 20-40 hours for businesses with 1,000 SKUs, involving standardizing product naming conventions, eliminating duplicate entries, and creating logical SKU hierarchies. Staff training demands 4-8 hours per employee for initial onboarding, plus potential shift overlap during implementation resulting in two weeks of doubled labor costs.[12]

Integration complexity varies depending on existing systems, potentially requiring IT consultation for connecting barcode software with accounting platforms, e-commerce sites, or enterprise resource planning (ERP) systems. Ongoing maintenance includes scanner battery replacements every 18-24 months, periodic printer head cleaning and replacement, label supply replenishment, and software subscription renewals.[12]

| Component | Entry-Level | Mid-Range | Enterprise |

| Barcode Scanner | $150-$300 | $500-$800 | $1,200-$3,000 |

| Thermal Printer | $300-$500 | $800-$1,500 | $2,500-$5,000 |

| Software (monthly) | $50-$100 | $150-$300 | $400-$1,000 |

| Label Materials | $20-$50/1000 | $50-$100/1000 | $100-$200/1000 |

| GS1 License | $30 single | $250+$50/year | $400+ annual |

| Training Time | 8-16 hours | 16-40 hours | 40-80+ hours |

Key Benefits and ROI for Small Businesses

Implementing barcode systems delivers immediate and measurable improvements across multiple operational dimensions. Labor cost reduction typically ranges from 15-30%, as tasks that previously required full-day manual counting can be completed in hours or minutes through rapid scanning. A retail customer processing 100 orders daily reported labor costs decreasing by 38% after barcode implementation.[2][20]

Inventory accuracy improvements represent perhaps the most dramatic benefit, with businesses typically achieving 99.8% accuracy compared to 96-97% with manual systems. This 3% improvement may seem modest, but eliminates thousands of dollars in losses from overselling, stockouts, and misplaced inventory annually. Studies demonstrate that manual barcode scanning yields approximately 63% inventory accuracy, while automated systems push accuracy above 95%.[7][20][2]

Error rate reduction approaches 90% as barcode scanning eliminates human data entry mistakes. These errors previously manifested as incorrect shipments, wrong prices at checkout, misplaced inventory, and customer service issues—all costly problems resolved through barcode implementation.[20][2]

Barcode systems deliver measurable ROI across multiple operational areas, with error rate reduction showing the most dramatic impact.

Most small businesses achieve complete return on investment within 6-12 months after implementing barcode systems. The payback derives from multiple sources: reduced labor costs saving $20,000-$50,000 annually for businesses processing 25-100 daily orders; lower inventory carrying costs decreasing by 10-30% through accurate demand forecasting; decreased emergency orders and expedited shipping expenses; and reduced customer service costs from fewer order errors.[2][20]

Inventory optimization enables businesses to reduce safety stock levels by 15-25% without increasing stockout risks, directly improving cash flow. With carrying costs typically running 20-30% of inventory value annually, a $100,000 inventory reduction adds $20,000-$30,000 directly to the bottom line. Companies implementing barcode systems report 42% faster identification of slow-moving products and 37% better forecasting accuracy, enabling data-driven decisions about promotions, purchasing, and inventory allocation.[20]

Customer satisfaction improvements yield long-term value difficult to quantify but crucial for sustainable growth. Businesses report 95-98% on-time shipping rates compared to 80-85% with manual systems, 35% decrease in order cancellations due to stockouts, and 25-30% reduction in customer service calls about order status. Since customer acquisition costs typically run 5-7 times higher than retention costs, these satisfaction improvements significantly enhance profitability.[20]

Implementation Process: A Step-by-Step Guide

A systematic six-step approach ensures smooth barcode system implementation for small businesses, from goal setting to staff training.

Step 1: Identify Your Inventory Goals

Begin by clearly defining what you want to achieve with barcode technology. Common objectives include enhanced theft protection through detailed asset tracking, improved order fulfillment accuracy, faster inventory counts, better demand forecasting, or assistance with FIFO (first-in-first-out) accounting methods. These goals will dictate which barcode types, hardware, and software best serve your needs.[5][21]

Step 2: Choose the Right Barcode System

Select barcode symbologies matching your operational requirements and industry standards. For retail sales, UPC-A or EAN-13 barcodes from GS1 are mandatory for products sold through major retailers or online marketplaces. For internal inventory tracking, Code 39 or Code 128 barcodes offer flexibility to encode custom information without GS1 licensing. For complex tracking needs requiring serial numbers, batch codes, or expiration dates, consider 2D codes like QR or Data Matrix that store substantially more information.[1][5][22][21]

Industry-specific requirements also factor into barcode selection: ISBN codes for books, FNSKU codes for Amazon FBA inventory, Codabar for libraries and blood banks, and GS1 DataMatrix for pharmaceutical track-and-trace compliance.[22][1]

Step 3: Select Software and Hardware

Choose inventory management software supporting barcode scanning and integrating with your existing business systems. Cloud-based solutions offer advantages for small businesses: lower upfront costs, automatic updates, accessibility from any device, and simplified IT management. Popular options for small businesses include Zoho Inventory starting at free plans, inFlow Inventory offering barcode scanning features, and specialized solutions like PackageX providing mobile-first barcode inventory management.[5][21][23]

Hardware selection should balance functionality, durability, and budget. For fixed locations like retail counters, wired USB scanners provide reliable, cost-effective scanning. For warehouse environments, wireless scanners enable mobility throughout facilities. For field operations or businesses starting small, mobile scanning apps transform existing smartphones into functional scanners at minimal cost.[10][14][13][5]

Step 4: Define Barcode Information and Generate Codes

Determine what data to encode in your barcodes. Common information includes product SKU numbers, storage locations, expiration dates, batch numbers, and manufacturer details. Different barcode types accommodate different data capacities—1D codes typically handle 8-20 characters, while 2D codes can store thousands of characters including complete product descriptions or URLs.[3][4][5]

For retail products requiring GS1 barcodes, obtain your Company Prefix or individual GTINs through GS1 US or your national GS1 office. For internal-only barcodes, free online generators like Sunavin, Barcode Producer, or software-integrated generators create professional codes supporting various symbologies.[18][22][17]

Step 5: Print and Apply Labels with Best Practices

Thermal printing technology represents the standard for professional barcode labels, offering two methods with distinct advantages. Direct thermal printing uses heat-sensitive paper that darkens when heated, providing cost-effective labels suitable for short-term applications like shipping labels or temporary inventory tags. These labels fade when exposed to heat or sunlight, limiting their durability. Thermal transfer printing transfers ink from a ribbon onto label material through heat application, producing highly durable labels resistant to chemicals, temperature fluctuations, and mechanical wear. This method suits permanent labeling needs in harsh environments.[24][25]

Visual guide to barcode placement best practices for optimal scanning

Label placement significantly impacts scanning success. Best practices include positioning barcodes on flat or consistently curved surfaces, avoiding corners, seams, or edges; placing retail product barcodes in the lower right quadrant of the back panel where scanners expect them; maintaining adequate quiet zones (blank margins) of at least 6mm on the left and 4.5mm on the right for EAN-13 codes; ensuring high contrast between bars and background, preferably black bars on white backgrounds; and verifying barcodes remain visible and accessible without requiring product rotation.[26][27][28]

Common placement mistakes to avoid include printing barcodes around packaging corners causing curvature, placing codes too close to edges risking quiet zone loss, positioning barcodes on transparent packaging without opaque backgrounds, applying labels over perforations or seams, and using glossy surfaces that create scanner interference.[28][26]

Step 6: Train Staff and Monitor Performance

Comprehensive staff training ensures successful adoption and maximizes system benefits. Effective training covers proper scanning techniques, handling various product orientations, troubleshooting common scanning issues, data entry procedures for items without barcodes, and understanding system workflows for receiving, picking, and shipping.[5][12]

Designate internal “super users” who receive advanced training and can assist other employees, reducing reliance on external consultants and controlling ongoing costs. Implement regular refresher sessions quarterly to reinforce proper procedures and introduce new features.[12]

Monitor key performance metrics to assess system effectiveness and identify improvement opportunities: scan success rate (target 99%+), inventory discrepancy levels (should decrease dramatically), time saved per cycle count, order fulfillment accuracy, and customer complaint rates related to inventory issues. Most businesses observe immediate improvements within the first month, with full optimization achieved after 3-6 months of consistent use.[21]

Integration with Business Systems

Point-of-Sale (POS) Integration

Integrating barcode scanners with POS systems creates seamless checkout experiences while maintaining accurate inventory records. The integration process typically involves selecting compatible hardware ensuring the scanner works with your POS software, connecting the scanner via USB or Bluetooth according to manufacturer specifications, configuring scanner settings to match barcode types and data formatting requirements, and testing extensively with various product barcodes before going live.[29][30]

Modern POS systems automatically update inventory levels when barcodes are scanned at checkout, preventing overselling and providing real-time stock visibility. This integration enables additional capabilities like automatic price lookups, sales tracking by product or category, customer purchase history analysis, and streamlined returns processing.[31][29]

E-commerce Platform Integration

For businesses operating online stores, integrating barcode systems with e-commerce platforms like Shopify, WooCommerce, or Amazon ensures inventory synchronization across sales channels. When properly configured, scanning products during receiving automatically updates stock levels in your online store, preventing the frustration of selling out-of-stock items.[32][33]

Advanced integrations enable marketplace fulfillment optimization, where barcodes facilitate order picking and packing for multiple sales channels from a unified inventory pool. Amazon FBA (Fulfillment by Amazon) operations particularly benefit from barcode integration, using FNSKU codes to track products throughout Amazon’s fulfillment network.[1][32]

Accounting Software Integration

Connecting barcode inventory systems with accounting platforms like QuickBooks, Xero, or FreshBooks automates financial record-keeping and provides accurate cost of goods sold (COGS) calculations. When inventory is received and scanned, costs automatically flow into accounting records; when products are sold, revenue and COGS entries generate automatically, maintaining synchronized financial and inventory data.[23]

Barcode Technology vs. RFID: Understanding the Alternatives

While barcode technology serves most small business needs admirably, understanding radio frequency identification (RFID) helps make informed technology decisions.[7][34]

| Feature | Barcode | RFID |

| Technology | Optical scanning | Radio frequency waves |

| Line of Sight | Required | Not required |

| Read Speed | Fast (one at a time) | Very fast (bulk reading) |

| Multiple Items | No, sequential scanning | Yes, hundreds simultaneously |

| Data Capacity | Limited (30-7,000 characters) | High (up to 8KB) |

| Durability | Can fade or damage | Very durable, encased |

| Cost per Tag | $0.01-$0.05 | $0.10-$100 |

| Inventory Accuracy | ~63% manual, 95%+ with automation | 95%+ automated |

| Implementation Cost | Low ($1,500-$8,000) | High ($20,000-$200,000) |

Barcodes excel when cost-effectiveness is paramount, universal standardization is required, line-of-sight scanning is practical, and gradual implementation is preferred. They remain ideal for retail checkout, basic inventory management, shipping labels, and compliance requirements where barcode standards are mandated.[34][7]

RFID advantages emerge in high-volume operations requiring bulk reading of hundreds of items simultaneously, environments where tags may be hidden or difficult to access, applications demanding real-time location tracking, and industries with harsh conditions where label damage is common. Apparel retailers increasingly adopt RFID for cycle counting entire stores in minutes rather than hours, while pharmaceutical companies use RFID for serialized track-and-trace compliance.[7][34]

Many businesses implement hybrid approaches, using barcodes for point-of-sale scanning and external shipping while employing RFID for internal warehouse operations. This combination leverages the cost-effectiveness and universal acceptance of barcodes while gaining RFID’s efficiency advantages for internal processes.[35][7]

Security and Anti-Counterfeiting Measures

As barcode technology becomes increasingly critical for supply chain integrity, security considerations grow in importance. Sophisticated counterfeiters replicate barcodes to introduce fraudulent products into legitimate distribution channels, necessitating advanced security measures.[36]

Modern security techniques include digital watermarking that embeds invisible encrypted information within barcode images, detectable only by specialized scanners; blockchain integration creating immutable records of each barcode scan throughout the supply chain, preventing data manipulation; serialization assigning unique serial numbers to each product enabling individual item tracking from production to point-of-sale; and spectral signature analysis using specialized ink compositions difficult to replicate, detectable through spectral analyzers.[37][36]

Two-factor authentication (2FA) enhances security by requiring secondary verification—such as a PIN code, biometric scan, or time-based token—even if a barcode is successfully duplicated. Luxury goods manufacturers increasingly implement this approach, allowing consumers to verify product authenticity through smartphone apps that scan barcodes and request additional authentication.[36]

Common security vulnerabilities businesses should address include exposure to cyber attacks through database connections, where compromised systems enable barcode data manipulation; inadequate verification processes using outdated scanners unable to detect counterfeit barcodes; and insufficient consumer awareness of barcode security risks, particularly QR code phishing scams redirecting users to malicious websites.[36]

Common Mistakes and Troubleshooting

Incorrect barcode symbology represents a frequent mistake, such as using EAN-13 instead of UPC-A for North American retail products. Each symbology encodes data differently; using the wrong type creates unscannable codes despite visual similarity. Barcode generation software typically suggests appropriate symbologies based on your data and intended use.[18][38]

Low contrast between bars and backgrounds causes scanning failures. While creative designs may use colors, scanners employ red light that perceives colors differently than human eyes—red appears light while blue appears dark. Black bars on white backgrounds provide optimal contrast; acceptable alternatives include dark blue, dark brown, or dark green bars on white, yellow, or orange backgrounds.[28][38]

Inadequate quiet zones (blank margins surrounding barcodes) prevent scanners from identifying code boundaries. Standards specify minimum quiet zone dimensions varying by symbology—typically 6mm left and 4.5mm right for EAN-13 at 100% magnification. Design elements encroaching on quiet zones cause consistent scanning failures.[39][28]

Print quality issues stem from worn printer heads creating missing bars or white lines, incorrect label and ribbon combinations causing smudging, improper printer settings resulting in bars too wide or narrow, and ink spread from failure to adjust for printing method characteristics. Regular printer calibration and maintenance prevent these issues.[40][28]

Placement and Environmental Problems

Curved surface placement distorts barcodes, making them difficult to scan. When cylindrical packaging necessitates curved placement, orient barcodes vertically (ladder orientation) to minimize curvature impact. Never fold barcodes around corners or place them under package flaps.[26][27][28][41]

Environmental damage from moisture, dirt, heat, or physical abrasion renders barcodes unreadable. Select label materials matching your environment: synthetic materials for outdoor or humid conditions, heat-resistant materials for high-temperature environments, and protective lamination for physically demanding applications. Direct thermal labels fade under heat or sunlight; use thermal transfer printing for permanent labels requiring durability.[25][36][28][40]

Barcode sizing errors create scanning difficulties when codes print too small or too large. Standards allow 80-200% magnification of nominal size, though maintaining 80-120% range ensures optimal scanning. Codes smaller than minimum specifications require extremely tight print tolerances and high-quality equipment.[28][38]

Check digit errors occur when the final verification digit in GS1 codes calculates incorrectly, causing system rejections. This typically results from manual entry mistakes. Always use validated barcode generators and verify codes through online validators before mass printing.[42]

Data formatting inconsistencies where barcode data doesn’t match system expectations cause scanning failures. Ensure your barcode format aligns with industry standards (GS1, HIBC, etc.) and matches your software’s configuration. Data formatting accounts for approximately 40% of scanning failures, making proper setup crucial.[42]

Compatibility problems arise when scanners cannot read certain barcode types—for example, laser scanners reading only 1D codes when 2D codes are present, or older systems unable to process certain symbologies. Verify your scanning hardware supports all barcode types in your operation before implementation.[3][11]

Future Trends in Barcode Technology (2025 and Beyond)

Two-dimensional barcodes are rapidly becoming industry standard, with QR codes now representing 25% of all barcode usage globally. The enhanced data capacity enables new applications: product authentication through blockchain verification, instant access to detailed product information via embedded URLs, dynamic codes that update content without reprinting labels, and marketing integration linking products to promotional content or customer engagement platforms.[37][43]

Major retailers are preparing for 2D barcode acceptance at checkout by 2027, driving significant infrastructure investment. This transition enables brands to encode rich product data including expiration dates, batch numbers, sustainability information, and allergen warnings directly in point-of-sale barcodes rather than maintaining separate databases.[35][37]

Integration with Internet of Things (IoT)

IoT-enabled devices equipped with barcode scanners enable real-time data capture and sharing across supply chains. Smart warehouse robots autonomously scan barcodes to update inventory levels without human intervention. IoT-connected scanners transmit data instantly to cloud-based systems, enabling managers to monitor operations remotely and respond to issues in real-time.[37][44]

RFID tags are becoming smaller, cheaper, and more capable, with integrated sensors monitoring temperature, humidity, and other environmental conditions. The convergence of barcode and RFID technologies creates hybrid systems where products carry both technologies—barcodes for universal compatibility and point-of-sale scanning, RFID for automated inventory tracking and loss prevention.[44]

Artificial Intelligence and Machine Learning

AI-driven barcode scanning improves recognition accuracy, especially for damaged or poorly printed codes. Machine learning algorithms analyze scan patterns to identify fraudulent activity, flagging anomalies for investigation. Predictive analytics derived from barcode scan data forecast demand trends, optimize inventory levels, and identify operational inefficiencies.[36][37][45][43]

Computer vision technologies enable smartphones and cameras to recognize products without requiring visible barcodes, supplementing traditional barcode scanning. This augmented reality integration overlays digital information onto physical products when viewed through smartphone apps, creating interactive product experiences.[37][43]

Enhanced Security Through Blockchain

Blockchain integration with barcode systems provides transparent, tamper-proof product histories from manufacturing through final sale. Each barcode scan records an immutable blockchain entry, enabling complete supply chain visibility and preventing counterfeit product infiltration. Pharmaceutical companies lead this adoption, using blockchain-verified barcodes to combat medication counterfeiting and ensure patient safety.[36][37][45]

Smart contracts automatically execute when barcode scans meet predetermined conditions, streamlining processes like payment release upon delivery confirmation or automatic reordering when inventory reaches threshold levels.[37]

Industry-Specific Applications

Barcode technology revolutionizes retail operations through accelerated checkout processes, real-time inventory visibility, seamless omnichannel fulfillment, and detailed sales analytics by product, category, or location. Small retail stores report 15% increases in monthly revenue after implementing barcode scanners due to faster checkout enabling higher customer throughput.[46][31]

Healthcare and Pharmaceuticals

Healthcare facilities use barcodes for medication verification preventing dosing errors, patient identification ensuring correct treatment, medical equipment tracking, and regulatory compliance for pharmaceutical serialization. Hospitals implementing barcode medication administration systems report 50% reductions in medication errors.[46][45][47]

Restaurants and catering businesses leverage barcodes for ingredient inventory management with FIFO tracking, recipe costing and menu engineering analysis, supplier receiving verification, and food safety compliance through expiration date monitoring.[46]

Manufacturers implement barcodes for work-in-process tracking, quality control checkpoints, component traceability, and labor efficiency measurement. Production efficiency typically improves 25-30% as barcode systems eliminate manual tracking and reduce work-in-process search times.[46][20]

Barcode technology in 2025 offers small businesses a proven pathway to operational excellence, combining affordability with transformative impact on efficiency, accuracy, and profitability. With basic systems starting around $1,500 and delivering ROI within 6-12 months, the investment threshold has never been lower while the competitive advantages have never been greater.[12][2]

Success begins with clear goal definition, appropriate technology selection matching your specific needs, and systematic implementation following proven best practices. Whether operating a retail storefront, online marketplace, service business, or manufacturing operation, barcode technology scales gracefully from initial implementation through business growth.[46][1]

The convergence of barcode technology with artificial intelligence, IoT, and blockchain creates unprecedented opportunities for small businesses to compete effectively with larger organizations through data-driven decision-making and operational optimization. Early adopters position themselves advantageously as these technologies mature and become industry standard.[37][43]

Begin your barcode journey by assessing your current inventory management challenges, researching suitable software solutions offering free trials, and experimenting with mobile scanning apps to experience the

- https://www.inflowinventory.com/blog/the-ultimate-barcoding-guide/

- https://www.finaleinventory.com/barcode-inventory-system/benefits-of-barcode-inventory-system

- https://www.scandit.com/resources/guides/types-of-barcodes-choosing-the-right-barcode/

- https://www.cognex.com/what-is/industrial-barcode-reading/what-are-the-types-and-parts-of-a-barcode

- https://www.scandit.com/blog/barcode-inventory-system-for-small-businesses/

- https://lowrysolutions.com/blog/what-is-the-difference-between-1d-and-2d-barcode-scanning/

- https://cybra.com/rfid-vs-barcode/

- https://www.gs1us.org/upcs-barcodes-prefixes/1d-vs-2d-barcodes

- https://scanbot.io/blog/types-of-barcodes/

- https://digital-link-qr-code.com/best-barcode-scanners

- https://tera-digital.com/blogs/barcodes/best-barcode-scanner

- https://www.finaleinventory.com/barcode-inventory-system/barcode-system-cost

- https://www.waspbarcode.com/buzz/tech-tools-5-smart-phone-barcode-scanner-apps

- https://www.asp.com.au/choosing-best-barcode-scanner-business/

- https://www.creativesafetysupply.com/qa/barcoding/is-it-expensive-to-implement-a-barcoding-system

- https://gs1.fi/en/gs1-company-prefix-and-barcodes-price

- https://www.gs1us.org/upcs-barcodes-prefixes/how-to-get-a-upc-barcode

- https://www.sunavin.com/barcode-generators-for-small-businesses/

- https://www.gs1uk.org/knowledge-hub/membership/how-much-does-gs1-uk-membership-cost

- https://www.finaleinventory.com/barcode-inventory-system/barcode-inventory-system-roi

- https://packagex.io/blog/barcode-inventory-system-for-small-business

- https://www.finaleinventory.com/barcode-inventory-system/barcode-inventory-system-for-small-business

- https://unicommerce.com/blog/best-barcode-inventory-managment-software/

- https://www.weber-marking.com/expertise/know-how/glossary/barcode-printer/

- https://www.xprintertech.com/using-thermal-printers-for-labels-and-barcode-printing

- http://www.onlinetoolcenter.com/blog/Best-Practices-for-Barcode-Placement.html

- https://www.gs1uk.org/knowledge-hub/barcodes/where-should-a-barcode-be-placed

- https://www.weyfringe.co.uk/barcode-verifiers-checkers-readers/barcode-mistakes-to-avoid

- https://possales.com.au/blog/how-to-integrate-a-barcode-scanner-with-your-point-of-sale-system/

- https://magefan.com/magento-2-pos-system/barcode-scanner-integration

- https://goftx.com/blog/pos-with-barcode-reader/

- https://www.shopify.com/blog/barcode-inventory-management

- https://rabiloo.com/blog/how-to-integrate-point-of-sales-pos-with-the-e-commerce-website

- https://retailcloud.com/rfid-vs-barcode-for-inventory-management/

- https://www.rfgen.com/blog/rfid-vs-mobile-barcoding-differences-use-cases/

- https://www.fastercapital.com/content/Barcode-market-research–Barcode-Security–Preventing-Counterfeiting-and-Fraud.html

- https://www.omegabrand.com/news/barcode-trends-to-watch-in-2025/

- https://www.barcodeproducer.com/articles/common-barcoding-mistakes-how-to-avoid-bad-barcodes

- https://www.loftware.com/resources/blog/2022/seven-reasons-why-your-barcodes-might-be-failing

- https://blog.barcodefactory.com/blog/5-barcode-printing-mistakes-you-might-be-making-and-how-to-fix-them

- https://barcodesavers.sg/common-barcode-mistakes-to-avoid/

- https://www.finaleinventory.com/barcode-inventory-system/common-barcode-problems-fixes

- https://www.finaleinventory.com/barcode-inventory-system/future-of-barcoding

- https://www.linkedin.com/pulse/future-barcode-rfid-technology-2025-chainway-india-yix3c

- https://blog.barcodefactory.com/blog/5-big-trends-in-barcode-and-rfid-technology-for-2025

- https://blog.barcodefactory.com/blog/why-small-businesses-should-invest-in-barcode-solutions-to-boost-efficiency

- https://www.idewod.com/blog/best-barcode-solutions-2025-technology-trends/

- https://www.inflowinventory.com/blog/best-barcode-scanner/

- https://www.kladana.com/blog/inventory-management/barcode-inventory-software/

- https://www.intermax.com.au/how-to-choose-a-barcode-system-for-small-business/

- https://www.effon.com/affordable-wireless-barcode-scanner-small-business-guide/

- https://www.activebarcode.com/codes/

- https://warego.co/blog/how-to-set-up-a-barcode-system/

- https://en.wikipedia.org/wiki/Barcode

- https://www.skunexus.com/blog/barcode-inventory-system-cost-ultimate-breakdown-guide

- https://www.barcode-us.com/gtins-prefixes-barcodes/gs1-barcode-service-pricing

- https://free-barcode.com/barcode/inventory-management/barcode-inventory-initial-setup-costs.asp

- https://www.easyreplenish.com/blog/top-6-small-business-inventory-control-software-free-paid

- https://www.reddit.com/r/barcodes/comments/1e4r08y/as_a_small_biz_just_starting_out_do_i_need_the/

- https://www.zoho.com/kw/inventory/barcode-software-small-businesses/

- https://www.hoinprinter.com/a-news-analyzing-the-cost-benefit-ratio-of-barcode-scanners-for-small-businesses.html

- https://www.gs1us.org/small-business

- https://www.qmhinc.com/barcode-vs-rfid/

- https://www.geeksforgeeks.org/computer-networks/difference-between-rfid-and-barcode/

- https://www.youtube.com/watch?v=qBZy_oJsSH4

- https://infraon.io/blog/barcode-asset-tracking-software-for-small-business/

- https://www.kuwaitlabels.com/product-category/printers/barcode-printers/

- https://www.assetpanda.com/resource-center/blog/benefits-of-barcode-asset-tracking-software-for-small-business/

- https://altavantconsulting.com/rfid-vs-barcode-inventory-tracking-2025/

- https://starlight-kw.com/collections/label-printers

- https://www.barcodesforafrica.com/blog/2024/06/25/the-roi-of-barcodes-how-a-small-investment-can-boost-your-profits/

- https://cpcongroup.com/cost-of-rfid-tags-vs-barcodes/

- https://wibi.com.kw/collections/thermal-label-printers

- https://acctivate.com/barcode-system-for-small-business/

- https://www.cykeorfid.com/rfid-vs-barcode-a-comprehensive-comparison-of-advantages-disadvantages-and-application-scenarios/

- https://www.dynamsoft.com/Documents/Best_Practices_for_Maximizing_Barcode_Reader_Technology.pdf

- https://www.barcoding.co.uk/barcode-app/

- https://developer.vuforia.com/library/vuforia-engine/images-and-objects/barcode-scanner/best-practices-for-barcode-scanning/

- https://www.codereadr.com

- https://www.barcodesinc.com/cats/barcode-scanners/apps.htm

- https://www.connectpos.com/top-pos-supporting-barcode-scanning/

- https://www.gs1us.org/upcs-barcodes-prefixes/how-to-use-your-upc-barcodes/place-barcodes-on-products

- https://play.google.com/store/apps/details?id=com.maiko.scanpet&hl=en

- https://dmsiworks.com/blog/best-practices-for-barcode-scanning-in-business-central-how-to-ensure-readability-and-accuracy

- https://play.google.com/store/apps/details?id=com.teacapps.barcodescanner&hl=en

- https://posiflexindia.com/why-barcode-scanners-are-essential-for-e-commerce-businesses/

- https://free-barcode.com/barcode/barcode-technology/popular-mobile-barcode-scanning-apps.asp

- https://free-barcode.com/barcode/barcode-types/prevent-barcode-counterfeiting-data-tampering.asp

- https://www.scantrust.com/secure-qr-code-anti-counterfeiting-solutions/

- https://alpvision.com/challenges-in-counterfeit-detection/

- https://www.hague-group.com/anti-counterfeit-barcode-labels-can-protect-your-brand/

- https://www.nature.com/articles/s41598-024-65450-1

- https://www.yhdaa.com/blog/navigating-2025-technology-trends-for-bar-code-scanners/

- https://tera-digital.com/blogs/barcodes/barcode-scanner-market

- https://www.teklynx.com/en/blog/8-common-barcode-mistakes

One response

This topic was very well presented. The explanation stayed clear, logical, and easy to follow from start to finish. Each point connected smoothly, which made the content both engaging and useful. Overall, it delivered great value in a simple and understandable way.